When the conversation turns to sustainability in the automotive world, electric vehicles tend to steal the spotlight. But for Singapore design house Pass It On Studio — the team behind GREEN-HOUSE, the country’s first and largest sustainable retail festival (its fourth edition was held in November) and a distributor of building materials made from upcycled food waste — the brief they handed to Hong Kong multidisciplinary design studio Editecture was refreshingly uncompromising: if it can’t live again, we don’t build it.

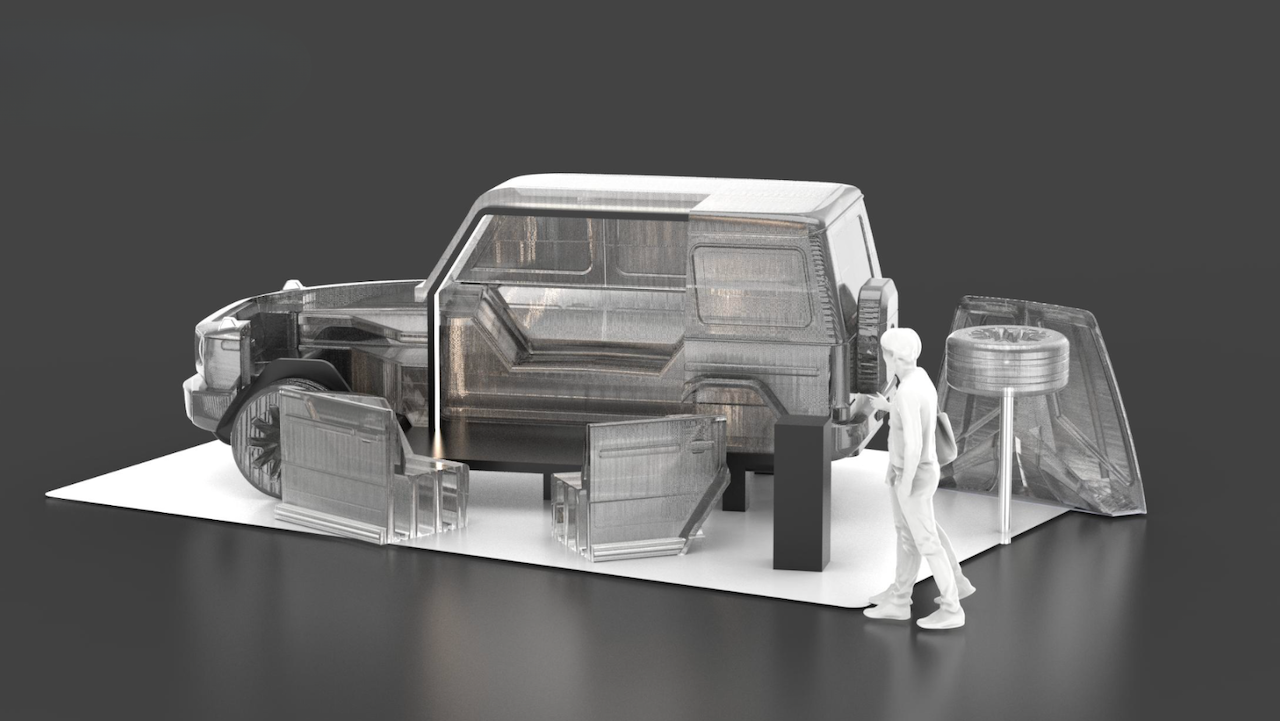

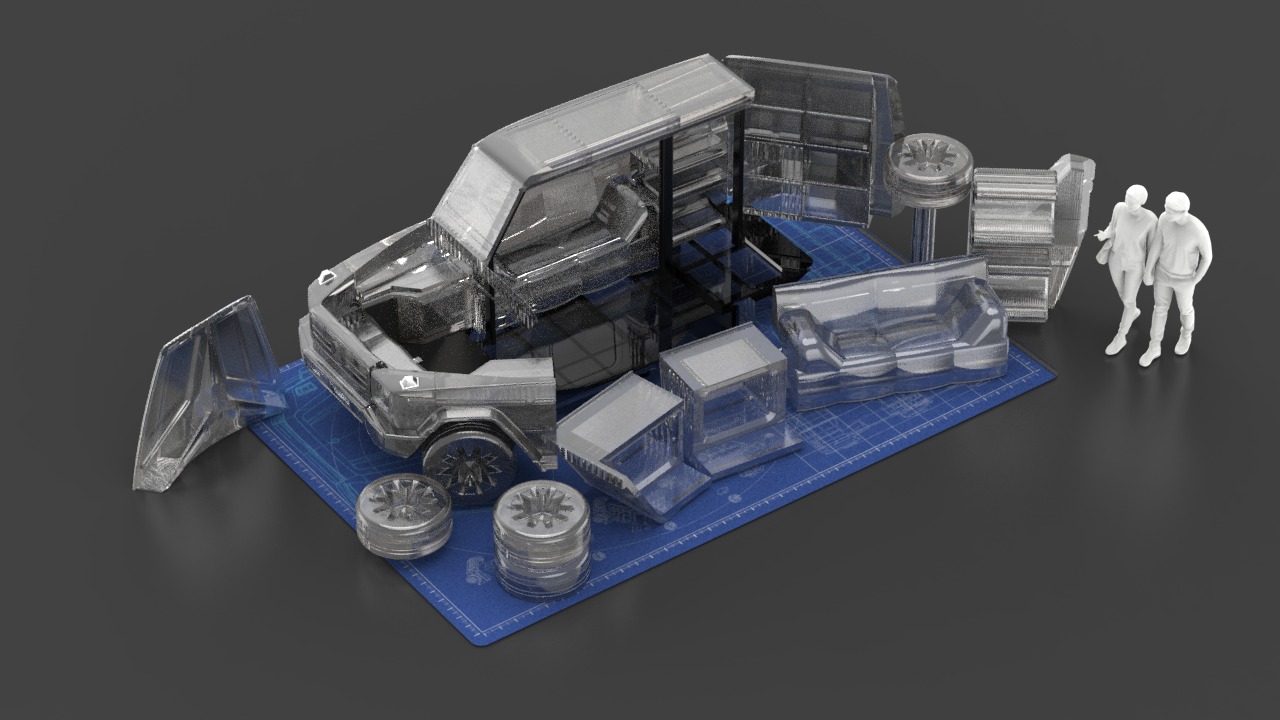

It sounded open-ended enough, especially when Editecture was paired with long-time GREEN-HOUSE partner Mercedes-Benz for a festival installation. Yet that direction crystallised into something remarkable: 580kg of “waste”, in the form of 40,531 discarded plastic bottles, 3D-printed into a life-sized replica of one of the marque’s most recognisable SUVs, the G-Class. Once the weekend festival wrapped, the structure was dismantled and transformed into furniture for the client’s offices and showrooms — a full-circle finale.

We dive deeper into the project to explore how circular design principles are reshaping the built environment.

How did you decide to pair Editecture and Mercedes-Benz for GREEN-HOUSE 2025?

Michelle Chow and Serene Tan, Co-Founders, GREEN-HOUSE (M&S): Mercedes-Benz is in its third year as a key festival partner at GREEN-HOUSE, and we shifted essentially from storytelling to “story-doing.” Mercedes-Benz brought an icon in evolution backed by a no-compromise belief that luxury and responsibility co-exist and compound through action; [Hong-Kong studio] Editecture brought an architect’s rigour to large-format 3D printing and a fixation on circular, accountable design—work that makes a statement and then goes to work. Together, we knew the partnership could turn a symbol of mobility into a modular furniture ecosystem, where rescued plastic re-formed into chairs, shelves and lamps—a statement you can sit on, and form built for its next life.

The installation was created using 40,531 discarded PET bottles—580kg of recycled plastic. Did using rPET result in any unexpected design or structural challenges?

Jacqueline Chak, Co-founder & Creative Director, Editecture (JC): Recycled plastic is unique and special in terms of the mixture of recycled plastic. While its structural strength is lower compared to steel and concrete, its performance benefits include significant weight reduction—slashing transportation emissions—and high durability, moisture resistance, and often a lower embodied carbon footprint.

That said, rPET required very intricate design study on the structural support to ensure the structural integrity. It demanded design compromises with thicker walls and engineered structural support to ensure the strength of the actual structure. While in terms of form, it enables highly efficient, lightweight, and complex geometries through 3D printing, using material only where structurally needed. It allowed us to perform and design with the complex curves in the G-Class model. For example, with the furniture components of the “afterlives” of the car, we had to apply a precise curved structural pattern. The texture often reveals its layered, printed nature, celebrating a unique, non-virgin aesthetic that requires no additional finishing.

M&S: This installation resulted in 580 kg of “waste”—captured, cleaned, and re-expressed as infrastructure you can sit on, work at, and redeploy. We’re not just diverting waste; we’re proving reuse at scale: measurable inputs, durable outputs, and public proof that good and responsible design can progress our society.

How do you see circular systems design—where materials and functions can evolve over time—shaping the future of architectural and product design?

JC: Circular systems design promises a transformative future for architecture and product design by embedding resilience and resource intelligence. It fundamentally reduces waste and environmental impact by keeping materials in continuous use loops.

For architecture, this means creating adaptable buildings where components like walls or fixtures can be easily disassembled, repaired, or repurposed, extending structural lifespans.

In product design, it enables modular goods that can be upgraded/ upcycled instead of discarded. It minimises wastage from the usage of virgin material, thereby lowering a project’s whole-life carbon footprint. It also fosters innovation in material reuse, ultimately creating a regenerative built environment that is dynamic, economically efficient, and ecologically restorative.

Beyond this showcase, what potential do you see for scalable applications of this approach in real-world urban or commercial contexts?

JC: In urban contexts, it can produce durable street furniture, public park elements, and low-cost housing modules, addressing both waste and public need.

Commercially, it's ideal for creating custom retail interiors, acoustic wall panels, and lightweight, sustainable partition walls. The agility of 3D printing allows for cost-effective, localised production, reducing transportation emissions. By transforming urban plastic waste into functional community assets on-site, this method can establish hyper-local circular economies, making it a powerful tool for sustainable city development and corporate ESG goals beyond a one-off showcase. Like this project, the showcase can be reused and upcycled to be reused again as 25 pieces of furniture, extending the lifespan of the showcase.

In organising GREEN-HOUSE over the years you have met designers, architects, brand owners. How do you feel that Asian designers and architects compare to the global scene when it comes to sustainability? M&S: Asia’s edge is constraint-driven ingenuity: dense cities, deep craft, and a cultural comfort with repair and reuse. On the ground, that looks like swap and thrift shops proliferating, micro-factories turning bottle waste into furniture, craft hands working with CNCs and 3D printers to prototype and iterate. Where we believe we can take a leaf (or two) out of global infrastructure and practices: shared parts and open specs so ideas travel faster, more public-private pilots, and procurement that mandates or incentivises durability and circularity. When policy meets design here, the region won’t just catch up—we will set the brief.

Looking ahead, how might you continue to bridge design, technology, and environmental responsibility in future projects? And how can architects and designers employ more ways to incorporate sustainability into their practices? JC: Editecture will continue dedicating our design methodology and research on sustainability to look for better solutions. To reach out and hopefully work on global collaboration to bridge our design with the world. We will explore design and adapt AI to create structures that are inherently efficient and aesthetically designed.

Our palette will evolve to include locally-sourced, bio-based materials and high-strength components crafted from local urban waste, closing the resource loop. We will continue to bridge the commercial world with our community. Through our work to give back not only to our community but to the world—creating a positive ecological footprint for generations to come.

M&S: They can make five moves, starting immediately:

- Design for disassembly (no glue where a screw will do).

- Material passports (where did it come from, what it is, how it comes apart, where it goes next).

- Localise supply (short, transparent chains beat exotic imports).

- Prototype with waste (treat streams as libraries, not landfills).

- Budget the afterlife (spec maintenance, take-back, redeploy).

Do this and every project becomes a mini-infrastructure for circular living.

Share

Share